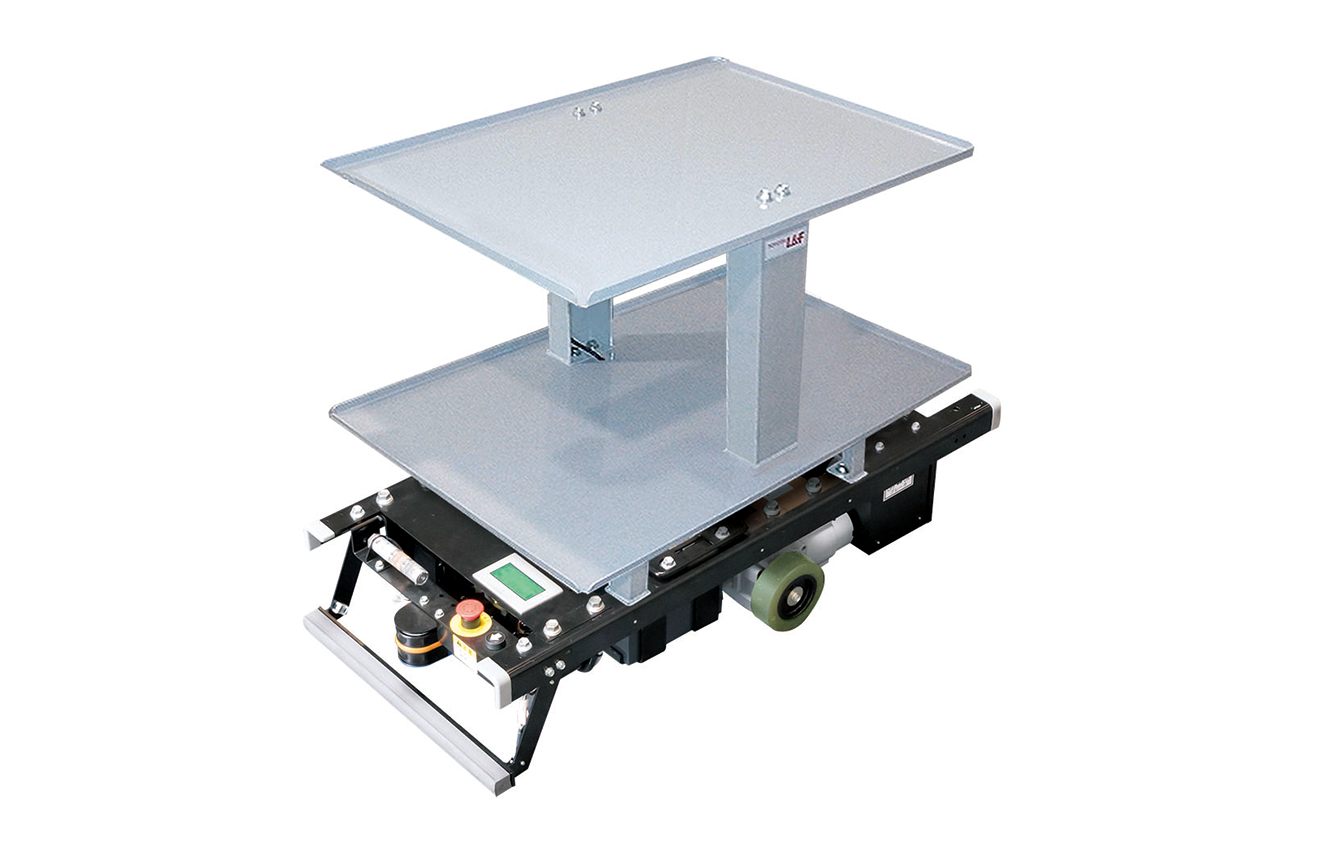

Standard Automated Cart – ATBE05

Toyota KEY Cart

Kaizen Easy Yourself

Improve production and sustain more efficient processes via guided vehicles with automation capabilities for optimal performance plus enjoy savings on resources, energy consumption, time and cost.

Automated carts are designed to automate repetitive and manual processes. These vehicles can be utilized for various material handling applications such as dolly transportation, sorting, parts supply system, and loading or towing.

Automated carts are simple and safe construct vehicles which require minimal monitoring for multi-uses. Each vehicle is compact enough for narrow spaces and versatile to switch up routes or tasks with a few easy adjustments or programming by Excel that can be customised by staff.

Simplify operations and take your business further with automated guided vehicles.

Standard Automated KEY Cart Features & Uses

Travel direction

- Forward

- Backward (optional)

Multi-transportation uses

- Direct loading: up to 200kg max load at 30m/min speed

- 3 points towing: up to 75kg max load at 30m/min speed

- 1 point towing: up to 750kg max load at 30m/min speed

Applications

- Supports various types such as loading and sneaking into a trolley

Industries

- Automotive

- Electronics

- Healthcare

- Manufacturing

- Warehouse & Logistics

Download Toyota-AGV-Keycart-Brochure.pdf

Productivity

Model types

- The Standard Automated KEY Cart is suitable for multi-purpose or multi-mode applications with direct loading and under frame towing.

- The Short Automated KEY Cart is suited to narrow and limited space applications with towing and single-direction functions.

Durability

Easy maintenance and customisation

- Drive modules are maintenance-free with brushless motor and chainless drive application.

- Adjustments and fittings can be easily done by staff or crew to meet task requirements.

- The layout settings are simple and a route change is achieved by magnetic tape guide while operational control is maintained by marker patterns.

Sustainability

User-friendly settings and programming

- All tasks are easily programmable and switchable using Excel® spread sheets.

- Control panels are touch screen and equipped with convenient multi-functions.

- Operational patterns such as pivoting and steering are available for maximum efficiency.

Couplings and attachments

- Vehicles can be adjusted and fitted for a variety of uses.

Body and peripheral options

- Parts and such as battery, whisker bumper, optical communication unit, master on switch, touch panel cover and more features can be added as required to suit tasks.

Safety

- Vehicles are equipped with safety scanners for preventive detection and safety speeds for collision-free work zones.